To oil and gas projects all around the Gulf, UAE, and other countries, we provide Janitza, Akytec products, and heat trace cables. We also deliver designed heat trace systems that keep process lines safe, keep product temperature constant, and meet hazardous-area standards. Speedy delivery around UAE centers and local support groups keeps initiatives on target.

The oil and gas sector needs steady heat control for pipelines, tanks, manifolds, and sample lines to keep plants running and safe. Harsh weather, long pipe runs, and remote sites create real risks for flow loss and product damage. We match the heat trace approach to the process needs so operators get reliable results and fewer surprises.

Pipes and sample lines can clog when fluids freeze or thicken, which halts manufacturing and raises expenses. We supply products that keep fluids at the right flow and prevent wax, hydrate, and paraffin build‑up. Our solutions keep process temperatures steady so meters and pumps work as intended and teams avoid emergency work.

Hazardous zones require careful product choice and strict wiring rules to avoid ignition risks. We select components that match the zone, and we train installers to follow safe methods on site. We also focus on energy use, so operators pay less for heat while they keep the process safe and stable. With our products, you will get:

Our staff supports customers in selecting the appropriate category and accessory set to guarantee the system runs from day one and remains simple to service. To keep power consumption minimal and uptime great, we match cable types to the fluid, pipe size, and control technique.

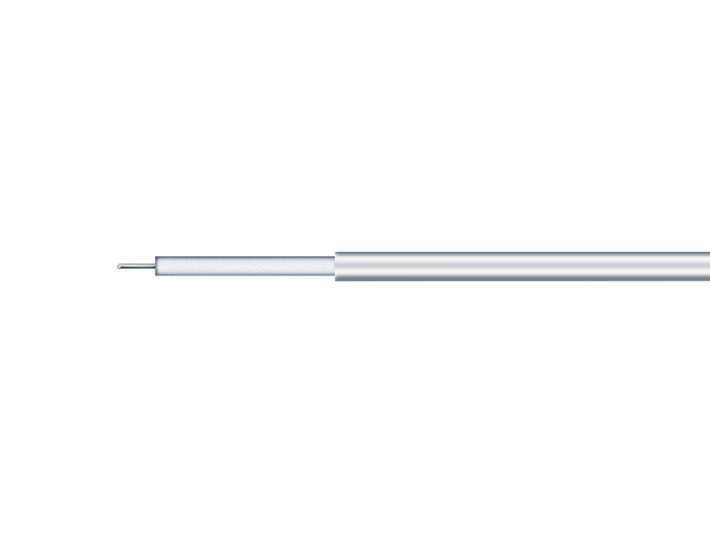

Constant Wattage Heating Cables deliver steady power where designers need fixed output.

MI Heating Cables give high reliability for critical lines and harsh conditions. Installing is made quicker and more robust with accessories like clips, terminations, and junction boxes.

uit long runs and places with changing temperatures because they adjust heat along the cable.

Pak Link LLC serves projects across the UAE and the wider Gulf region from regional hubs that hold stock and spare parts. We keep local inventory to shorten lead times for critical items and to help teams restore service quickly when issues arise. Our logistics teams plan deliveries to match project schedules and to meet tight windows when clients need urgent spares.

Our teams keep recommended spare lists for each project so operators avoid long outages and maintain steady production.

We deliver systems to meet recognized standards such as IEC and IEEE, and we reference ATEX and IECEx where hazardous‑area equipment applies. We collect manufacturer test certificates and record installation checks so clients can show proof during audits. Our documentation includes cable trace records, insulation test results, and photos that help inspectors and operations teams verify the work.

We select items that fit the zone categorization and craft explicit installation instructions so that on-site teams adhere to safe procedures. Our method ensures that every design choice prioritizes safety and guarantees that projects pass inspections without needing final-minute modifications.

We apply heat trace systems to many real tasks on oil and gas sites. Our teams tailor each solution to the fluid type, the line length, and the site access. We balance power needs with control strategies so systems run efficiently and meet the operator’s targets for uptime and cost. Contact us now because we:

Pak Link LLC brings product know‑how and regional experience to every project. We supply trusted brands and match product capabilities to the job. Having a local presence enables us to rapidly move components and assist on-site staff when deadlines approach. To provide customers with a complete solution rather than only components, we mix engineering and field services with product supply.

Our teams work with client engineers to reduce design changes and to keep projects on budget. We focus on clear communication, accurate documentation, and practical installation guidance so operations teams gain confidence in the system and can maintain it with ease.

Contact Pak Link LLC to review your heat trace needs and get a clear plan for protection and temperature control. Our heat trace experts suggest the most appropriate product category and offer a realistic installation and commissioning strategy. Reach out to set up a project review or ask for a customized quote so we may assist you in maintaining constant and safe output.

Paklink LLC provides self-regulating, mineral insulated (MI), and constant wattage heat trace cables designed for pipelines, refineries, offshore platforms, and other oil & gas applications.

Heat trace cables maintain optimal temperatures, prevent freezing, control condensation, and reduce corrosion, ensuring safe and efficient operation of pipelines and equipment.

Oil & Gas refineries, upstream and midstream pipelines, LNG terminals, offshore platforms, and petrochemical plants across UAE and Gulf countries can benefit from Paklink LLC heat trace solutions.

Yes, Paklink LLC offers complete heat trace services including design, installation, automation integration, corrosion protection, and ongoing maintenance for Oil & Gas projects.

Paklink LLC combines expert engineering, a wide range of heat trace cable types, automation solutions, and corrosion protection to ensure reliable, safe, and efficient Oil & Gas operations.