At Pak Link LLC, we deliver tested heat trace solutions for construction projects across the UAE and the Gulf. You can count on us to get valuable products from Janitza and Akytec. We always provide quality components and ship them fast to project sites.

Frosty evenings followed by blazing afternoons play havoc on supplies and schedules across job sites. When mercury drops, glue turns sluggish, waterways stiffen, and equipment sputters without warning. Right heat trace components arrive, so teams push forward instead of stalling under costs that pile up fast.

When a sealant thickens or a pump malfunctions as a result of cold temperature, work can be stopped, and expenses increased. Wrong parts on the job slow things down and cause rework, which then makes the schedule go off and pushes milestones back. By providing cables, accessories, and spares suited for the task, we assist teams in avoiding those issues. Our buying process reduces the chance of wrong items arriving and keeps installation moving.

Our stock helps protect temporary water feeds, heating loops for curing, and process lines that must stay warm during installation. Our team works with site staff to match product families to real needs, not to a generic checklist.

We stock solutions that protect freshwater systems, fuel transfer lines, heating loops for curing anti‑corrosion coatings, and process piping that must remain warm during installation or transit. Our engineers consult with ship electricians and offshore technicians to match product types to the vessel’s operational profile.

We list product categories so buyers can pick the right family for each task and avoid confusion at the site gate.

Constant wattage cables work well for fixed heat needs and control schemes that crews prefer for repeatable tasks.

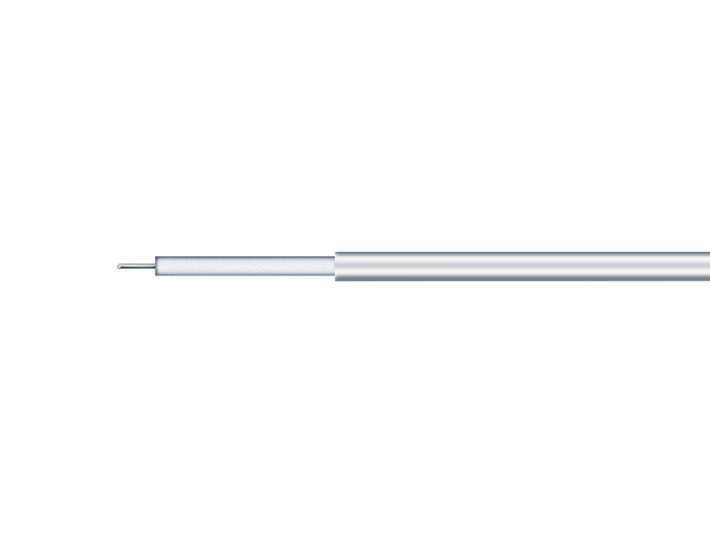

MI cables serve high‑temperature or long‑life needs where robustness matters and teams need durable parts that last. Accessories include power kits, sensors, junction boxes, and control gear that installers need on day one. Our staff checks part numbers and packs kits, so crews get what they need in one shipment and do not hunt for missing items.

Self‑regulating cables suit variable temperatures and long runs where power control matters and installers want simple wiring.

We always support you by making procurement simple and reliable. Our staff reads vendor datasheets and confirms compatibility so installers avoid surprises on site. We provide step‑by‑step installation notes that match the product type and the common layouts we see on projects. When teams need help, our technical staff answers questions and points to the right spare parts, so work moves on without long pauses.

We serve projects across the Gulf with a focus on speed and clear communication so teams do not wait for parts. Fresh batches arrive just in time when demand spikes, timed neatly with setup steps to keep the area clear. What shows up on truck lines up exactly with what goes into walls, cutting clutter where workers move.

Starting early, our team talks with buyers and location coordinators to match delivery times with gate openings plus lift equipment plans. What drives us isn’t complex – delivering correct pieces exactly where needed just when workers are ready, avoiding holdups on site.

We supply products that reference global standards, and we show the certificates that manufacturers provide so site safety officers can review them.

Once vendors provide materials, the team collects test reports along with documentation – smoothing out inspection steps and transferring records. Because of this, staying compliant feels easier, and audit hiccups happen less often.

We see the same problems on many sites, and we stock the parts that solve them. For example, a tower project used self‑regulating cable on temporary risers to avoid frozen lines during a cold snap, which saved days of work and reduced repair costs.

Another contractor used MI cable for a permanent pump skid where long life and high temperature mattered, and the parts performed through harsh site conditions. Our role is to supply the right category and the right accessories so installers can finish work on time and hand over systems that work.

Contact Pak Link LLC to secure heat trace parts for your construction site. Your project details, how long it’ll run, along with any tough location requirements – share those, then we get back fast with a straightforward price, delivery time, plus paperwork. Speed matters here because downtime slows everyone down.

Paklink LLC supplies self-regulating, mineral insulated (MI), and constant wattage heat trace cables for pipelines, building systems, and infrastructure projects in the construction sector.

Heat trace cables prevent freezing, maintain optimal temperatures, control condensation, and protect pipelines and building systems from corrosion in construction projects.

Commercial buildings, industrial construction, infrastructure projects, water pipelines, and HVAC systems in UAE and Gulf countries can benefit from Paklink LLC heat trace solutions.

Yes, Paklink LLC offers full design, installation, automation integration, corrosion protection, and ongoing maintenance services for construction and infrastructure heat trace systems.

Paklink LLC combines expert engineering, a wide range of heat trace cable types, automation solutions, and corrosion protection to ensure safe, reliable, and efficient construction projects.