Pak Link LLC delivers inventive, heavy‑duty heat trace and thermal management systems engineered for the demanding rhythms of industry across the UAE and the Gulf. We provide parts made to resist dust, vibration, chemical exposure, and ongoing usage in refineries, chemical facilities, power plants, and construction yards by working with reliable manufacturers like Janitza and Akytec. Local inventories and quick dispatch keep vital lines running to ensure production goals and outage windows stay in place.

Factories face tough conditions – grit in the air, sharp fumes, wild heat changes, yet constant strain on parts. That mix often leads to hotspots where gear stutters, seals crack, glue won’t set, fluids slow down. Our way stays grounded, ahead of breakdowns:

This technique reduces unexpected downtime, maintains product quality, and shortens maintenance windows.

We group products by function so engineers can quickly select the correct family for each application.

suited to valve jackets, meter runs, and fixed‑heat process lines requiring predictable heat output.

chosen for high‑temperature headers, steam tracing, and long‑life critical services inside furnaces and skids.

ideal for outdoor pipe racks, sample lines, and instrumentation conduits where ambient conditions change.

We act as an extension of plant engineering teams, not just a supplier. Our technical services include:

This collaborative model speeds acceptance testing and reduces the back‑and‑forth that stalls handovers.

Unexpected stoppages often trace back to a handful of thermal failures. We solve them with targeted products and field‑tested practices.

Blocked transfer lines and viscous fluids

Our Self‑regulating cable on transfer and sampling lines to maintain flow and prevent crystallization or gel formation.

Instrumentation and sensor drift

Localized trace with thermostatic control and RTD monitoring to keep sensors within calibration bands.

Adhesives and coating cure failures

Controlled heat loops for curing bays and coating skids to ensure consistent polymerization and adhesion.

Valve and actuator freeze

Use our Constant wattage jackets and redundant feeds for critical valves to guarantee operation during cold snaps.

Each solution is paired with installation guidance and spare lists so fixes are permanent, not temporary.

We align deliveries to outage schedules and shift patterns so parts arrive when crews are ready to install. Our logistics and documentation practices focus on traceability and audit readiness.

These measures smooth inspections and classification reviews while keeping projects on schedule.

We see recurring pain points across plants and stock parts that address them. Our role is to match product family and accessories to the process so installations finish on schedule and systems perform reliably.

Pak Link LLC supplies robust thermal systems built for heavy industry. Starting with what you need, hand over details like project size, key deadlines, how fast things must move, along with limits found onsite – then expect back a custom plan covering which items fit best, costs involved, when deliveries arrive, plus required paperwork. Production keeps moving only if pieces show up on time; upkeep becomes steady, too. Our goal? Getting exact supplies into place exactly when needed, helping your facility run without hiccups, day after day.

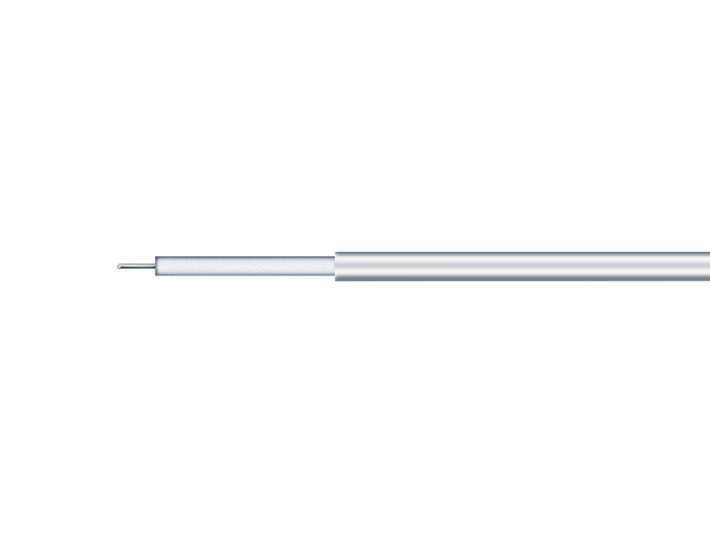

Paklink LLC supplies self-regulating, mineral insulated (MI), and constant wattage heat trace cables for industrial facilities, manufacturing plants, and process industries.

Heat trace systems maintain process temperatures, prevent freezing, control condensation, and protect pipelines and equipment in industrial operations.

Manufacturing plants, chemical processing facilities, food & beverage factories, pharmaceutical units, power plants, and water treatment facilities across UAE & Gulf countries can benefit from Paklink LLC solutions.

Yes, Paklink LLC offers automation integration, corrosion protection systems, and complete thermal management solutions alongside heat trace installation and maintenance.

Paklink LLC combines advanced heat trace cable technologies, expert engineering, and industry-focused solutions to ensure safe, efficient, and reliable industrial operations.