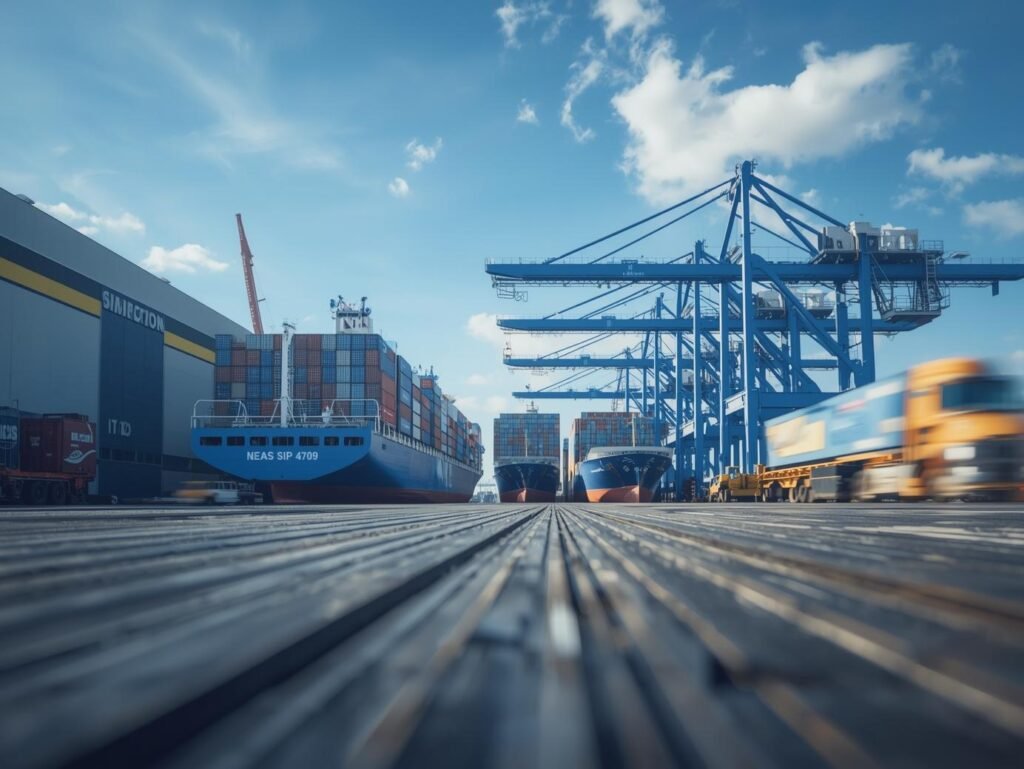

Pak Link LLC provides robust heat trace and industrial solutions designed specifically for maritime environments across the UAE and the Gulf. We partner with reputable manufacturers such as Janitza and Akytec to bring dependable components to shipyards, ports, and offshore facilities. Fresh gear reaches docks fast, keeping sea tasks moving. Speed meets care right where ships load. Every piece arrives on time, so work never stalls near water.

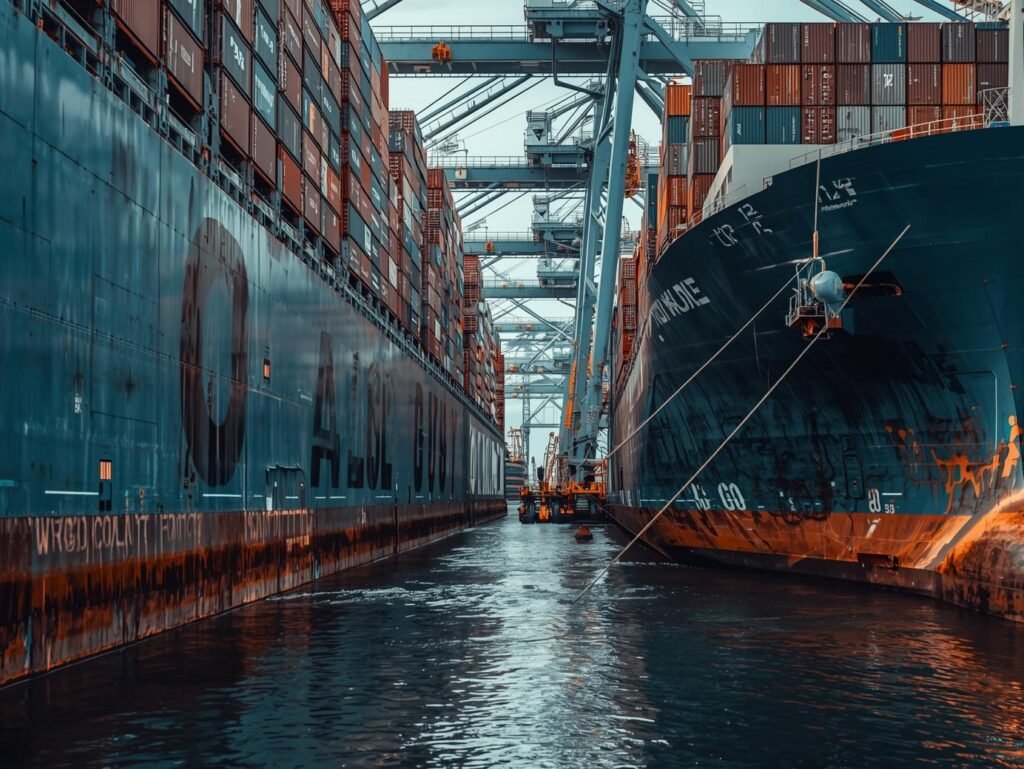

Out on the water, damp air mixes with salty spray and wild weather shifts – tough on gear. Cold hits hard; grease turns sluggish, parts lock up, pipes may clog. Proper heating tape keeps things moving, so work stays on track, shipments stay safe, and surprises get sidestepped.

Midway through a job, frozen pipes or glue that won’t stick might stall everything. When pumps quit without warning, ships sit idle longer than planned. Instead of smooth sailing, faulty gear leads to redoing tasks, pushing back test runs on the water. Starting with better materials helps – like heating cables built to handle life at sea. These include ends and backups made for tough conditions. Fewer mix-ups arrive when orders are verified before shipping. That way, fixes happen faster, time is saved, and repairs stay on track.

We stock solutions that protect freshwater systems, fuel transfer lines, heating loops for curing anti‑corrosion coatings, and process piping that must remain warm during installation or transit. Our engineers consult with ship electricians and offshore technicians to match product types to the vessel’s operational profile.

We categorize products, so ship engineers can quickly choose the correct family for each application and avoid confusion at the dock.

Constant wattage cables are preferred for fixed heat loads like manifold heating and repeatable process lines.

Mineral insulated cables are selected for high‑temperature or long‑life installations in engine rooms and critical skids. Saltwater gear needs tough parts that won’t rust, like power setups built to handle moisture, connection hubs rated for wet conditions,

Self‑regulating heating cables are excellent for variable exposure areas such as deck runs and exposed pipeways where automatic power modulation is beneficial.

We make procurement and technical coordination straightforward for shipyards and vessel operators. Our team reviews vendor datasheets and confirms compatibility with marine electrical systems and classification requirements. We provide detailed installation instructions that reflect typical vessel routing and structural constraints. When questions arise, our technical staff offers prompt guidance and points to the correct spare parts so commissioning proceeds without extended delays.

We support ports, shipyards, and offshore campaigns with a focus on speed and precise communication so teams do not wait for parts. Fresh stock moves out right when drydocks open, lifts roll in, and berths clear – keeping gear off the ground. Stuff shows up on the dock only if it fits today’s pipe runs or skid builds, slashing downtime hunting parts.

Starting early with procurement teams helps match supply timing to ship schedules along with crew shifts. What drives us stays clear – getting the correct components where they need to be, exactly when needed, keeping vessels moving without delay.

We provide products that reference international standards and supply manufacturer certificates for review by class surveyors and port authorities.

Our team gathers vendor documentation and test reports to streamline inspections and transfer records, reducing friction during audits and classification checks.

We encounter the same operational pain points across vessels and platforms, and stock the parts that address them. For instance, a coastal tanker used self‑regulating cable on cargo line manifolds to prevent wax formation during cooler nights, which reduced off‑hire risk and avoided costly cleaning.

A naval shipyard specified MI cable for critical steam lines where longevity and high temperature resistance were essential, and the installation endured demanding sea trials. Our role is to supply the correct product family and accessories so installations finish on time and systems perform reliably.

Keeping water and service pipes warm prevents bursts and cuts emergency repairs. Proper temperatures also help adhesives and coatings cure, so the hull stays strong. With our products, you can keep pumps and valves at the right heat to avoid delays during handover. Our work also helpsto ensure concrete curing correctly for quays and foundations, so structures are set as planned.

Local stock and fast dispatch reduce drydock and berth waiting times. Parts are checked and packed into ready‑to‑use kits to lower returns and rework, and our team makes sure the right items arrive. We provide clear technical help and supply vendor documents to make installation easier for crews. When available, we include certificates and test records so every item can be traced.

Pak Link LLC supplies tough heating parts built for ships, docks, or platforms far offshore. Share what you need – job size, how long it’ll take, plus anything tricky about where it’s going – then expect a fast answer with pricing, when it arrives, and needed documents. Late gear hurts work on water since idle time piles up expenses quickly.

Paklink LLC supplies self-regulating, mineral insulated (MI), and constant wattage heat trace cables designed for marine vessels, offshore platforms, and port infrastructure systems.

Heat trace systems maintain pipe temperatures, prevent freezing, control condensation, and protect critical equipment from corrosion in harsh marine and offshore conditions.

Ships, offshore oil platforms, LNG terminals, shipyards, coastal infrastructure, and port facilities across UAE & Gulf countries can benefit from Paklink LLC solutions.

Yes, Paklink LLC offers corrosion protection systems along with automation integration and heat trace installation to ensure long-term reliability in marine environments.

Paklink LLC combines advanced heat trace cable technologies, offshore-ready engineering solutions, and corrosion protection expertise to support safe and efficient marine operations.