Our experts deliver the best Industrial Automation services that make factories smarter and more efficient. We design solutions that match your exact needs, using clear steps and proven tools. Our team builds strong systems that start working right away, and we stay by your side for support. Pak Link LLC never cuts corners, so you get reliable performance and real savings in energy and labor.

We stand out among automation companies because we focus on simple designs and honest talk. Our work in automation engineering brings higher output, less downtime, and lower costs. Pak Link LLC treats your goals as our own, so you reach them on time and on budget.

Here are the Automation Services we Offer.

We install Programmable Logic Controller units that take charge of pumps, motors, and valves according to your rules. Our team ties each PLC into your current machines, tests every function, and provides clear screens so you see plant status at a glance. We program custom logic that automates routine tasks while logging key data for your engineers.

We equip your setup with features that simplify operations and planning:

These upgrades in your i&c system let your team shift focus from fixes to improvements.

Our Distributed Control System scales from a single unit to a full plant without extra fuss. We plot your process flow, pick the right points to measure, and link controllers so they share data and act fast on changes. Also, we deliver redundancy options that keep key loops running even if one controller goes offline.

We train your operators on intuitive graphic displays so they spot off-spec values and react right away. You track batch runs, manage recipes, and handle alarms with confidence. Over time, this approach raises safety, cuts waste, and smooths out production swings.

Get Industrial Automation Equipment that drives accuracy in your plant by using top-quality sensors, transmitters, and actuators that suit harsh conditions. We test every device for shock, heat, and moisture resistance so you see true readings on pressure, flow, level, and temperature. We only supply gear that stands up to daily wear and shows clear status lights.

At the same time, we guide you through each option and highlight key advantages:

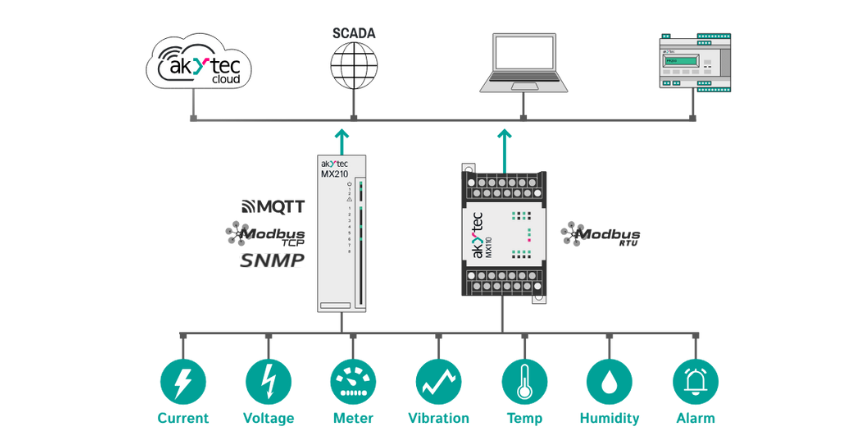

Industrial Automation Systems we offer tie together PLCs, HMIs, and SCADA into one easy dashboard. Our experts map your network, code clear logic, and set up data paths so you see alarms, trends, and reports all in one place. We test each link to avoid slowdowns, data loss, and security gaps.

We focus on the core strengths of our systems:

We provide Advanced Control Systems that apply model-based control to predict how your process behaves under changes in feed or energy cost. We create digital twins of your equipment, simulate control strategies, and fine-tune loops for tighter regulation. You get smoother product quality, less scrap, and lower energy use.

We install adaptive loops that learn your plant’s patterns and auto-tune setpoints for peak performance. Our team walks through every change with your engineers so you never face surprises. With us, your process stays stable, efficient, and ready for new challenges.

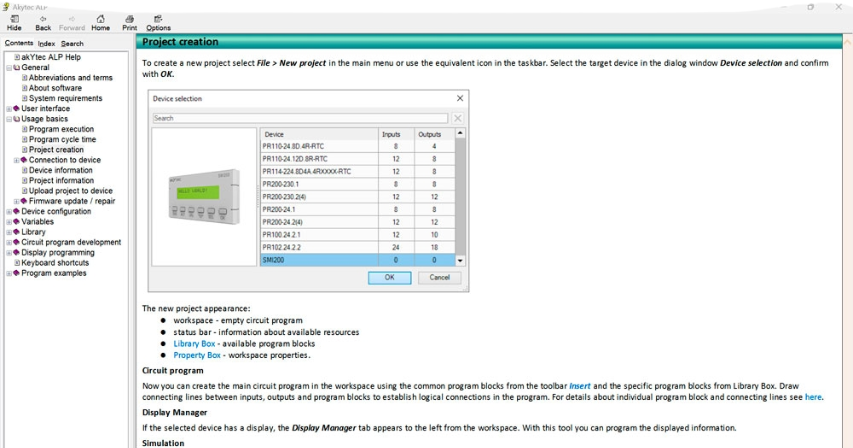

Our PLC Programming involves writing code in ladder logic, function block, or structured text based on what fits your plant and your team. We follow strict naming rules and add clear comments so future updates feel simple. We deliver robust code modules that you can test in a simulator before we go live.

Likewise, we map every I/O point, run full diagnostics, and share flowcharts that show each decision step. You get a tested program package that drops straight into your control room. Our experts back up every script with a setup guide and live support for a seamless startup.

As the leading PLC Troubleshooting service providers, our team jumps in with a clear plan to find and fix the issue fast. We log into your network or head to your site to check power, wiring, and program errors. Our experts trace signals, swap spare parts, and debug code until we find the root cause.

Our process includes:

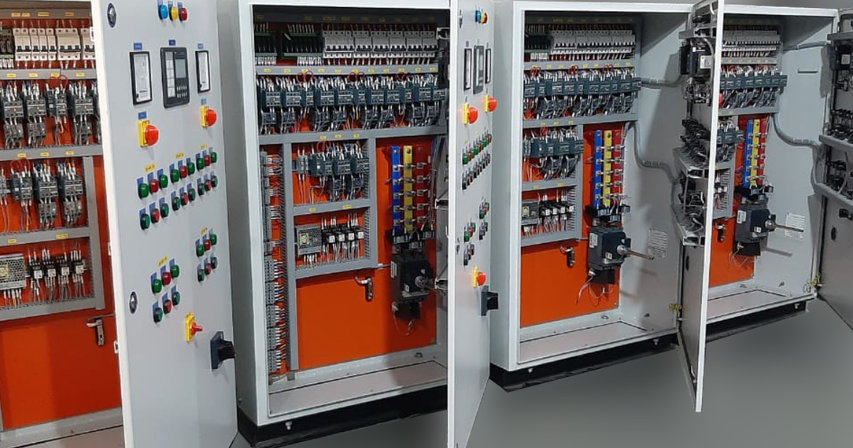

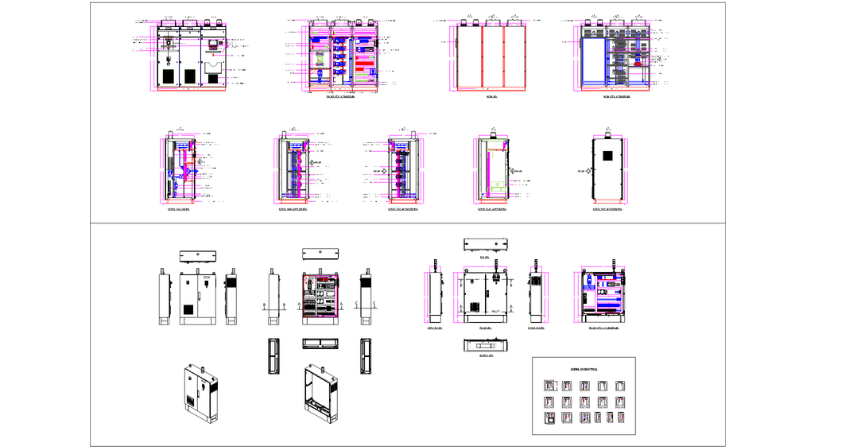

Our PLC Base Control Panel houses your PLC, power supplies, relays, I/O modules, and network switches in one neat cabinet. We size the enclosure for your space, add fans or heaters based on your climate, and label every terminal. We generate clear wiring diagrams so electricians hook up power and signals with no guesswork.

At the same time, we perform insulation checks, heat-run tests, and loop-back verification before we ship. You receive full test documentation and a field-wiring checklist so installation at your site feels smooth and error-free.

PLC Pump Panel delivers fluid-handling control that matches your process needs. We integrate VFDs, motor protectors, level switches, and pressure sensors in one panel that fits your pump room layout. Moreover, we design control logic that runs pumps in sequence or on demand, with backup options for critical lines.

We bench-test each panel for full start, stop, and fault conditions under simulated load. You get a complete FAT report, wiring guide, and commissioning checklist. Our team stands by to guide your installers through hookup, start-up, and hand-over so your pumps run smoothly from day one.

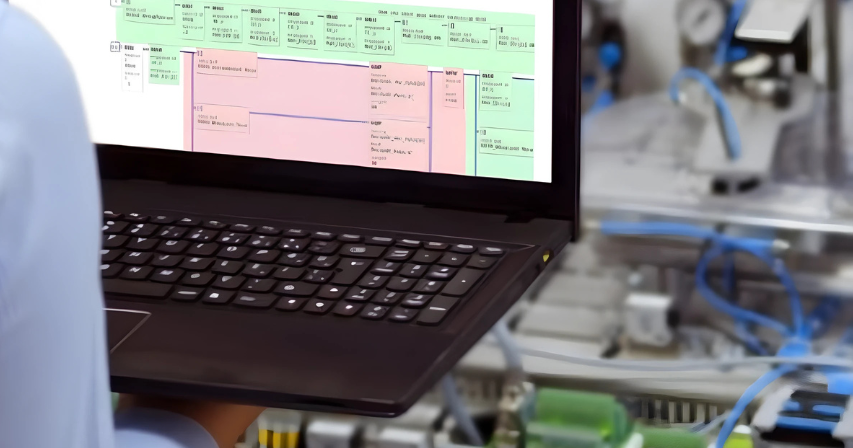

Our experts build SCADA dashboards and HMI screens that show your process story at a glance. We highlight key numbers, output rate, energy use, alarm status, so you see problems before they grow. We pull data from PLCs, sensors, and other devices into one view that anyone can understand. Consider our services because we:

Our team verifies each screen with you before launch to confirm it fits your workflow. We build a SCADA system that scales with your goals and keeps your plant running at peak efficiency.

As one of the top industrial automation companies in UAE, we create control panels that house PLCs, relays, power supplies, and HMIs with neat wiring and clear labels. Our CAD-driven layouts free up space and ease maintenance. We follow UL, CE, or local rules, wire with care, and run full tests before we ship. You get as-built drawings, component lists, and wiring diagrams to keep on file.

We also pick and tune field devices, flow meters, pressure gauges, temperature sensors, to give you precise data. Our team matches instruments to your media and environment for long-term accuracy. We perform loop checks and provide calibration certificates so you trust every reading from day one.

We become your single point of contact for big projects, taking charge of planning, hardware sourcing, and team coordination. Our project managers keep you in the loop with clear timelines, milestone updates, and risk reports. We run FAT (Factory Acceptance Tests) and SAT (Site Acceptance Tests) so you step into a working system on day one.

Our consulting goes beyond tech. We audit your processes, measure ROI, and map out upgrade paths that fit your budget. We draw on best practices from top industrial automation service providers to make sure each dollar you spend drives real gains. So, with us, you will get a full plan linking people, machines, and data into one smooth workflow.

Give us a call today for a no-cost process review. Our experts will show you how smart controls, clear data, and hands-on support fit your goals. Let’s work together to boost your output, cut costs, and lead your industry in performance with the best Industrial Automation services.

We help many fields with their automation needs. We work in food and drink, oil and gas, water treatment, auto plants, medical supplies, packaging, cement, steel, and warehousing. Our experts learn each sector’s rules so we meet your standards. You gain a partner who knows your field inside out.

We put senior engineers on every job, so you tap deep know-how from day one. We map and simulate your processes before code hits the PLC, saving you time on site. Our designs follow lean ideas to keep things simple and fast. We hand you clear docs and training guides for a smooth handover.

Yes! We handle design, parts buying, wiring, start-up, and training as one package. We manage all the trades and approvals so you don’t juggle vendors. Also, we run complete site tests to make sure your line runs right away. We leave you with full as-built drawings, user guides, and an empowered team.

Yes we do. For this purpose, we audit your current setup and design a plan that fits without excess change. We map communications among PLCs, sensors, and networks so data flows cleanly. We write custom drivers when off-the-shelf options won’t work. Our goal is to upgrade your plant without long stops.