The UAE hosts big oil, gas, shipping, and power projects. Engineers place many Junction Boxes around pipelines, tanks, and platforms. These boxes sit where gas or dust can appear. Clients and regulators demand strong rules like ATEX and Ex d to cut risk and meet law. The hot Gulf sun, salty air, and busy ports shape how teams pick and keep gear. Use Junction Boxes in UAE that match the site risk and last in Gulf conditions.

What Ex d means for Junction Boxes

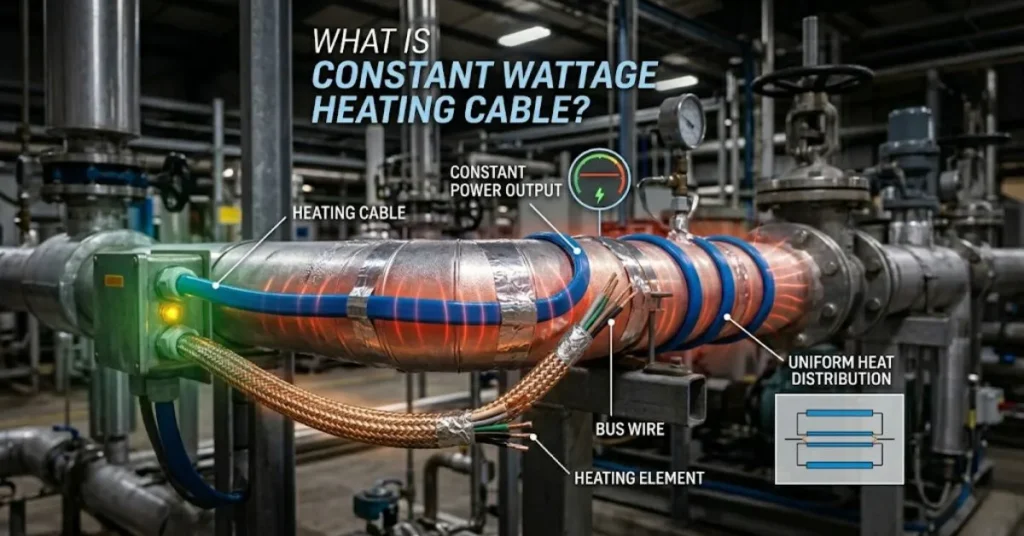

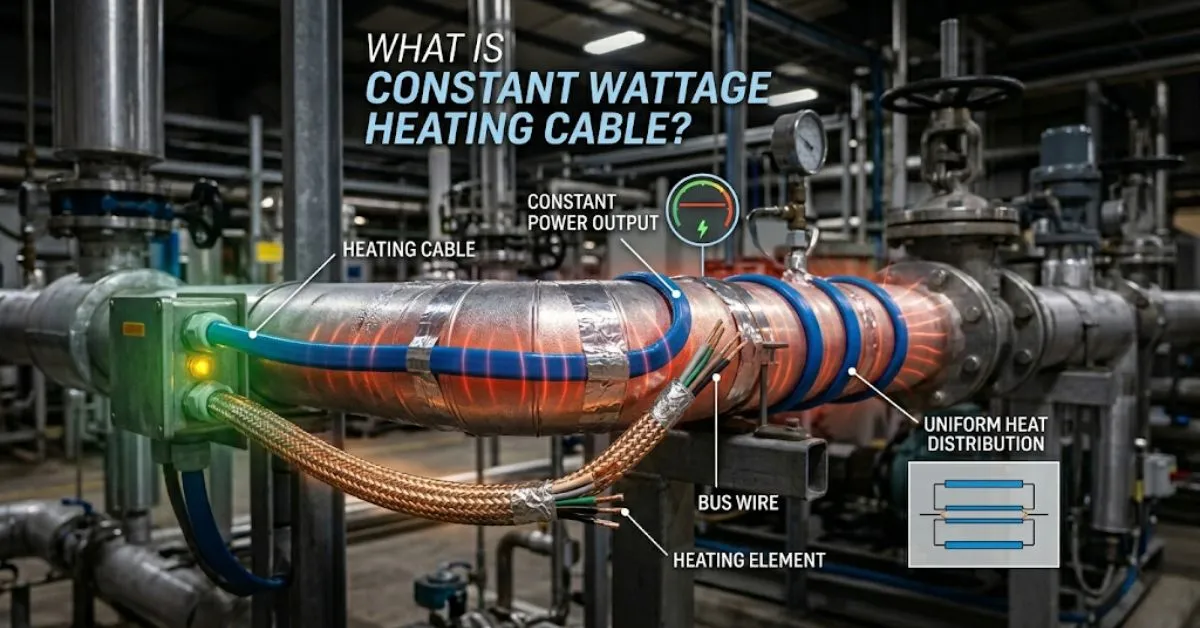

“Ex d” means a metal case keeps flames inside if a spark starts. Engineers design the case so fire stays inside and cools before it leaves joints. Manufacturers cut tight paths where hot gas can’t jump out. Choose Ex d for places where metal boxes suit the work. Use them with certified marks and clear instructions.

- Key needs: strong material; tight joints; certified glands; correct terminals.

- Use cases: oil plants, fuel stations, onshore and offshore piping.

- Related work: plan Trace Heating System Installation where pipes need heat control.

Why the UAE and Gulf need strict explosion protection

The UAE runs many plants onshore and offshore. Salt air and heat speed rust and wear. Clients expect ATEX or IECEx proof for boxes and gear. Local teams check equipment closely during handover. Engineers often pick stainless steel 316L or heavy coatings to resist coastal corrosion. Keep clear records for local authorities and owners.

- Gulf climate: hot days, humid coasts, sand and dust in deserts.

- Offshore needs: stronger corrosion control and regular checks.

- Project demand: fast approvals when suppliers include full documents and test reports.

How to pick the right Junction Boxes for your site

Choose gear that matches the hazard and the environment. Match zone rating, temperature class, and material.

Quick selection checklist

- Certification: choose ATEX/IECEx marked units.

- Zone rating: match box to the site’s hazardous area classification.

- Material: prefer stainless steel 316L in coastal zones.

- IP rating: pick Ingress Protection IP66 or better.

- Accessories: use certified glands, terminals, and clamps.

Design and materials for flameproof Junction Boxes

Design matters. Manufacturers make different shapes and sizes. Study the design and the mark before you buy.

Materials and finishes

- Stainless steel 316L resists rust and stands up to salt air.

- Aluminium gives a light option for dry indoor spots.

- Powder-coated carbon steel offers lower cost where corrosion risk stays low.

Seals and flamepaths

- Makers machine cover joints to tight tolerances.

- Use approved gaskets and avoid thread sealants that block flamepaths.

- Fit glands and entries that carry the same rating as the box.

Temperature class and marking

- Check the temperature class and gas group on the nameplate.

- Match the box surface temperature to the ignition temperature of the gas or dust.

- Keep the plate clean and visible.

Site installation rules that lower risk

Installers must follow the certificate, the maker’s guide, and local rules. A proper install keeps the box working as tested.

- Mount boxes on firm, prepared surfaces.

- Fit only ATEX/Ex d rated cable glands and ferrules.

- Tighten cover bolts to the torque the maker states.

- Keep flamepath faces clean and free of paint or sealant.

- Label the zone and equipment group at the location.

Maintenance and inspection

Maintenance keeps the protection working. Create a simple schedule and log each check.

Routine inspection items

- Check for rust, dents, or paint damage.

- Tighten cover bolts and gland fittings to spec.

- Check wiring for hot spots or loose terminations.

- Replace old gaskets and seals.

- Keep nameplates and markings readable.

Plan extra inspections in coastal and offshore areas.

Common site mistakes and how to avoid them

Field teams make repeat mistakes. Spot them early.

- Use only certified glands and accessories.

- Do not paint over the nameplate or markings.

- Avoid swapping a certified box for a cheaper non-certified unit.

- Do not overload terminals or exceed space for heat dissipation.

- Let only trained staff work on Ex d units.

Faults in heating lines can affect box temperature and safety.

Documents and certification you must keep

Project teams must store clear records. Good paperwork speeds approvals and handovers.

Essential documents

- Manufacturer certificate showing ATEX/Ex d compliance.

- Test reports and material specs.

- Installation drawings with a zone map and box locations.

- Commissioning records and torque check lists.

- Maintenance logs and inspection reports.

How local suppliers and contractors can help

Choose vendors like Pak Link LLC who know Gulf rules and local conditions. They can deliver stock items and advise on design, materials, and installation. Ask suppliers for local support and site visits. They often supply full packs: boxes, glands, terminals, and docs. That pack helps inspectors and reduces delays.

- Look for local stock and quick support.

- Ask for training for your electricians.

- Get spare parts and replacement gaskets on site.

- Request a clear supply list with part numbers.

- Consider supplier commissioning where available.

Cost matters and buying tips

Certified Junction Boxes cost more than basic units. The higher cost saves downtime and reduces risk. Compare offers on total value, not just price.

- Check what the supplier includes: glands, terminals, mounting kits.

- Ask about warranty and local repair options.

- Confirm lead times and stock levels.

- Verify the certificate scope and test reports.

- Keep spares for quick repairs.

Compliance checklist for ATEX Ex d in UAE

Follow this list to reach compliance on site.

- Survey the site and make a clear zone map showing hazardous areas.

- Pick Junction Boxes with the right ATEX/IECEx marks and temperature class.

- Choose material and IP rating for the Gulf climate and coastal salt.

- Fit only certified glands and terminals and follow torque data.

- Record installation steps and have a qualified engineer sign off.

- Add Trace Heating System Installation wiring diagrams and test sheets.

- Run regular inspections and keep logs for audits.

How to Save Money

Keep things simple to avoid trouble. Train staff to follow the maker’s guide. Replace worn gaskets. Fit the right paint and coatings. Keep spare certified parts on site. Review records and act on trends like repeated corrosion or loose bolts.

Recommended materials and why they work

Pick materials that last in Gulf weather. Use stainless steel 316L for coastal and offshore sites. Also, use aluminium in clean indoor areas to save weight. Use coated carbon steel where corrosion stays low.

- Stainless steel 316L: best for salt spray and humidity.

- Aluminium: light and cheaper for dry locations.

- Coated carbon steel: lower cost in protected areas.

Training and permits on site

Train electricians and technicians on Ex d basics and safe work. Use permit-to-work systems for any open work. Let only qualified people open a box or change wiring. Keep a log of training and competencies.

- Provide tool lists and torque wrenches.

- Keep the maker’s installation guide in the site folder.

- Use tags and lockout for any live work.

- Check the work with a competent engineer before you re-energize.

- Update records after any change.

Trace heating teams must carry certification and checks related to the Trace Heating System Installation tasks.

Closing Remarks

Buy robust equipment and handle it right through design, install, and maintenance. Work with suppliers who bring full certificates, spares, and local knowledge. Train your teams to follow the maker’s rules and keep good records. Plan for the climate: choose stainless steel 316L, fit Ingress Protection IP66, and use the right glands.

When you need heat control on pipes, include Trace Heating System Installation in your project plan and link it to the electrical and safety checks. Use Junction Boxes that match the zone and the environment. Keep the nameplates clear and the paperwork tidy. Good preparation reduces risk, avoids delays, and keeps people safe.

FAQs

Which zones suit Ex d junction boxes?

Use Ex d boxes in areas where gas may appear but not always. Engineers use them mostly in zone 1 and zone 2. For continuous gas (zone 0), choose other protection methods.

- Zone 0 needs intrinsic safety or purging.

- Zone 1 often accepts Ex d.

- Zone 2 can use Ex d with the right spec.

- Confirm with a hazardous area survey.

- Mark the area clearly.

How often should I inspect junction boxes in the UAE?

Inspect at least once a year for most sites. Inspect more often in offshore or coastal sites. Check immediately after any impact or modification.

- Annual visual check at minimum.

- Coastal/offshore: every 6 months.

- After storms or mechanical hits: immediate check.

- After wiring changes: re-check torque and seals.

- Keep records for audits.

Can my team open an Ex d box for repair?

Yes, but only when they follow a safe work permit and the area stays safe. Isolate power and work with a competent person. Replace any seals and test before you restore service.

- De-energize circuits.

- Use permit-to-work systems.

- Have a competent engineer supervise.

- Refit gaskets and torque bolts per spec.

- Record the work in the maintenance log.