Looking for an instrument and control system that can see, decide, and act instantly turns complicated work into smooth operations? From the first sensor signal to the last motor movement, our solutions keep every part of production running the way it should. We provide top-quality Industrial control systems to help your plant stay steady, cut energy waste, and maintain high quality every single day. We care about giving you the right tools to keep moving forward.

At Pak Link LLC, we offer reliable instrument control system installation services for industries in every state of the UAE. Our experts work closely with clients to set up systems that control, monitor, and protect vital processes. These systems help reduce downtime and keep your operations safe and efficient.

Whether you need a new setup or are upgrading an old one, we make sure it works exactly how your business needs it. Our team at Pak Link LLC handles all types of Electrical and Instrumentation projects, no matter how complex. We know how to work with I&C systems, distributed control systems, and advanced control systems, making us a trusted E&I contractor.

We install, and test everything ourselves, so you don’t have to worry about calling multiple companies. If you are looking for a reliable E&I sub-contractor, our team at Pak Link LLC is ready to support your projects with complete E&I services from start to finish.

Our experts handle Skid E&I Work in UAE with complete care and skill. We make sure your skid packages are safe, accurate, and ready for use in your operations.

We support industries that use pressure vessels by offering complete E&I work to monitor and control pressure levels with precision.

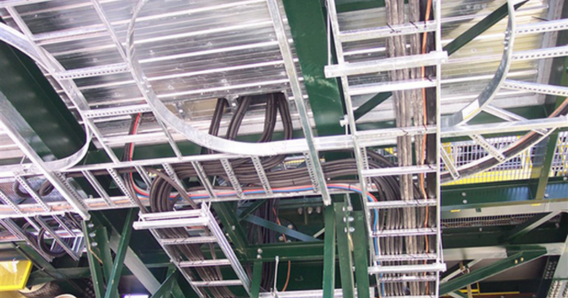

Our cable tray setups help keep your wiring neat, safe, and easy to maintain. This service is key in any project with complex cabling.

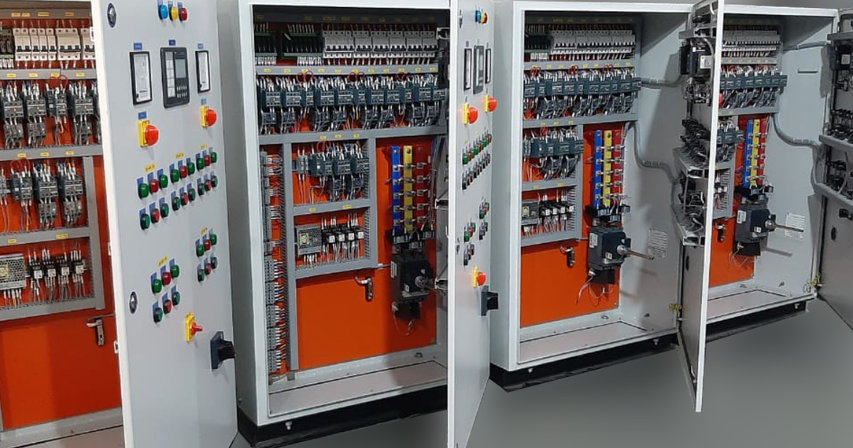

In areas with gas, dust, or explosion risks, we offer EXD Panel Installation to protect your systems and workers.

As a leading E&I company abu dhabi, we deliver E&I automation services to help your systems run with fewer mistakes and less manual work.

In our E&I installation services, our experts manage full Electrical and Instrumentation Installation Work across many sectors. We make sure every wire, sensor, and device works perfectly.

Our cable glanding services protect your wiring from water, dust, and wear. We use high-quality glands to secure each cable.

We provide cable termination services to make sure all your wires are safely connected and easy to maintain.

Label cables clearly for future service

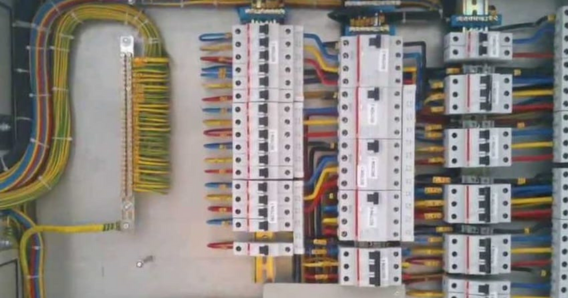

With our panel dressing services, we make sure your panels are organized, safe, and simple to troubleshoot.

We offer expert cabling services for both low and high-voltage systems. Our team handles planning and installation with precision.

We know that clean and tidy cables are important for both safety and system health. Our cable dressing services help you maintain order.

Improve system cooling and reduce risk of short circuits

We provide SS Tubing Fabrication and Installation using top-grade stainless steel, perfect for clean and tough environments.

Pressure-test tubing lines before handing over

Our pneumatic tubing installation services help your air-powered tools and systems work without leaks or delays.

Test airflow to check for any leaks or blockages

Rely on us for the best Skid & Rack Packages E&I Work to help your systems arrive ready to plug and play.

Our instrument control system installation services support many industries that need accurate and safe control. Our team handles every project with care and industry-specific knowledge. These are some of the sectors we serve:

Let Pak Link LLC help. Our experts can plan, install, and test everything with care, speed, and skill. We cover every UAE state and serve all major industries. We don’t just install systems—we build long-term solutions that help your business grow safely and efficiently. Call us or send a message today. Let’s make your systems smarter, safer, and ready for the future.

Paklink LLC provides a wide range of services, including Skid & Rack Packages, Pressure Vessel E&I Work, Cable Tray Installation, EXD Panel Installation, Electrical & Instrumentation Automation, PLC Pump Panels, Cable Glanding & Termination, Panel Dressing, SS Tubing, Pneumatic Tubing, and complete E&I installations across all UAE states.

Skid & Rack Packages and Pressure Vessel E&I work ensure that equipment is pre-assembled, tested, and ready for plug-and-play installation. This reduces field labor, minimizes downtime, and guarantees safe and reliable operation of industrial systems.

Industries such as Oil & Gas, Power Plants, Water Treatment, Chemical, Food & Beverage, Marine & Offshore, Mining, HVAC, Refineries, Industrial Automation, Construction, and Pharmaceuticals rely on these services for accurate monitoring, process control, and safe, efficient operations.

Yes. Pak Link LLC can assess existing I&C systems and integrate modern sensors, controllers, PLCs, and automation software. This ensures seamless operation, improved efficiency, reduced energy waste, and minimized disruptions to ongoing industrial processes.

Proper installation, calibration, and testing of electrical and instrumentation systems—such as EXD panels, PLCs, cable management, and tubing—ensure accurate monitoring, prevent system failures, reduce energy loss, and maintain safety compliance across industrial operations.