In 2023, companies spent over $210 billion on industrial automation. A study of 600 engineers found that 72% of projects ran late because control systems failed to match plant needs. Downtime in the process industries averages a cost of $20,000 per hour. To avoid such losses, the majority of companies or firms that are involved in the process industry will opt for Instrument And Control Services, these are firms that offer full system design, installation, and support. The choice of partner requires clear goals, budgets, and checks of past work.

Understanding Instrument And Control Services

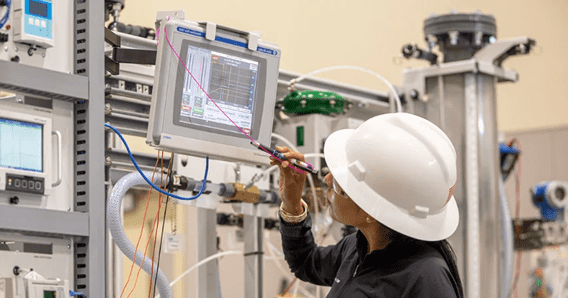

They cover everything from planning sensor layouts to tuning control loops. Experts help define what devices will monitor pressure, flow, temperature, and levels. They also set up controllers that read sensor data and drive valves or motors. By having a single team manage all details, companies cut miscommunication risks.

Moreover, using a dedicated service provider means faster problem fixes on site. Clients gain access to certified technicians and proven workflows. As a result, startups and veteran plants alike see smoother launches and fewer field issues.

Key Parts of an Instrument And Control System

Every system has core parts that must work in harmony.

- Sensors gather data on process variables like pressure or temperature.

- Transmitters convert sensor signals into standard outputs such as 4–20 mA.

- Controllers analyze inputs and issue commands to final control elements.

- Actuators adjust valves, dampers, or drives to keep processes steady.

Also, historians and human-machine interfaces log data and show trends on screens. When these parts connect smoothly, operators spot faults early.

Matching Project Needs

Complex processes often involve many loops, devices, and safety checks. Teams face the challenge of detailing every control point without missing a single item. In high-pressure projects, scope slips happen when people underestimate the number of I/O channels or signal types.

Alternatively, holding in-depth workshops with process engineers and operators brings clarity. Drafting simple diagrams that show each sensor and its wiring path helps everyone spot gaps. As workshops wrap up, project documents reflect true needs and avoid late changes. For this purpose, the role of the Instrument And Control Services is crucial.

Handling Tight Budgets

Every plant has financial limits that shape design options. High-end pressure transmitters can cost up to 40% more than basic models. Cheaper gear might work at first, but it often lacks built-in diagnostics and field calibration features.

Besides price tags, factor in lifecycle costs like repair, spare parts, and firmware updates. Asking vendors for total cost of ownership data helps teams compare bids fairly. Equally important involves carving out a small buffer for unexpected add-ons or urgent replacements.

Missing Skills and Training Plans

Sophisticated control systems demand more than basic operator skills. Field personnel often lack practice in network configuration or advanced calibration routines. As a result, on-site teams stall when they face complex alarms or communication errors.

Notably, crafting a hands-on training plan solves many issues early.

- Schedule interactive workshops on HART, Profibus, or Ethernet/IP basics

- Assign senior technicians to coach juniors during start-up phases

- Develop online modules covering routine checks and safety tests

Consequently, teams gain confidence and avoid mistakes that cause delays.

Meeting Safety and Rule Needs

Plants must follow tough safety rules mandated by agencies. Equipment often needs specific certifications for hazardous areas or emissions control. Missing a single paperwork item can halt a project or trigger heavy fines.

Meanwhile, setting up a compliance calendar ensures every audit, test, and recertification happens on time. Companies can use simple checklists to track device tags, certification dates, and test records. Keeping digital backups of certificates speeds up reviews when inspectors arrive.

Connecting Old and New Gear

Legacy devices often speak old protocols, while new controllers favor digital standards. In many plants, available control services struggle to link old 4–20 mA loops with Ethernet/IP networks. Engineers must fill protocol gaps without risking plant uptime.

Likewise, running a protocol-mapping exercise clears common hurdles.

- List each device, its protocol, and its data tag names

- Simulate data flow using a software tool before ordering hardware

- Build small interface racks that convert signals when direct links fail

By testing these links early in a workshop or lab, teams avoid nasty surprises on site.

Picking a Reliable Vendor

Instrument And Control Services often include long-term support, so vendor strength directly affects plant uptime. Looking at financial reports, customer case studies, and parts availability paints a clear picture of a provider’s stability.

Conversely, focusing only on low bids can end up costing more when vendors vanish or delay spare parts. Asking past clients about warranty responsiveness and on-site support speed reveals real strengths.

Keeping Projects on Track

Changes happen in every project. Stakeholders may ask to add a sensor, swap a controller model, or alter alarm limits. Those shifts can affect wiring, programming, and testing schedules.

Consequently, having a formal change log brings order. Recording each request with dates, cost impact, and approval status links every tweak back to its origin. Regular progress calls keep all teams aligned on scope and dates.

Extra Tips for a Smooth Start

Getting off on the right foot stops small issues from growing into big delays. Simple steps at kick-off make a world of difference.

- Define clear roles: who handles hardware, software, or safety checks

- Build a small prototype or mock-up panel to spot wiring mistakes early

- Agree on data-tag naming rules before writing any code

- Set up a shared folder for drawings, certificates, and test reports

Such groundwork cuts confusion and lays out a clear path to commissioning day.

Measuring Success and Learning

After go-live, teams gain vital insights from real data and field feedback. Tracking key metrics shows how well control loops hold targets and how often alarms sound. Engineers can aim for loop error rates under 2% and alarm counts below five per day.

Additionally, a short lessons-learned session highlights what teams did right and what could improve. Recording those notes in a central knowledge base benefits every future project.

In Closing

Choosing the right Services demands more than comparing price lists. Teams must weigh technical fit, vendor health, staff skills, and rule requirements. By planning deep, training hard, and testing early, projects run smoother and hit deadlines. At every step, solid checks and clear records keep tasks on track. Those habits turn tough control projects into dependable success stories.