UAE heat tracing sector grew fast in recent years. Industries in Dubai, Abu Dhabi, and Sharjah use electric heat tracing to protect pipes and keep chemicals at the right temperature. Oil refineries in Ruwais rely on systems to keep pipelines at 80 °C during cool desert nights. Desalination plants on the Palm Jumeirah run heat tracing lines to stop salt clogging. Engineers track projects that push the UAE market from USD 45 million in 2025 to an expected USD 78 million by 2033. This guide covers Constant Wattage vs Series Resistance Heat Tracing Cables in clear terms.

You will learn how each cable type works, spot their strengths and weaknesses, and choose the best fit for your project. We use easy words and an active voice. You find tables, bullet lists, and simple steps to make your job smoother.

Benefits of Constant Wattage vs Series Resistance Heat Tracing Cables

When you compare Constant Wattage vs Series Resistance Heat Tracing Cables, you see clear gains for each type you:

- Get fixed heat output with constant wattage cables.

- Gain field-cut flexibility with series resistance cables.

- Avoid cold spots on long runs using constant wattage cables.

- Reduce material waste on short runs with series resistance cables.

- Match power needs easily when you split a network into circuits.

Understanding Heat Tracing Cables

What Is a Constant Wattage Cable?

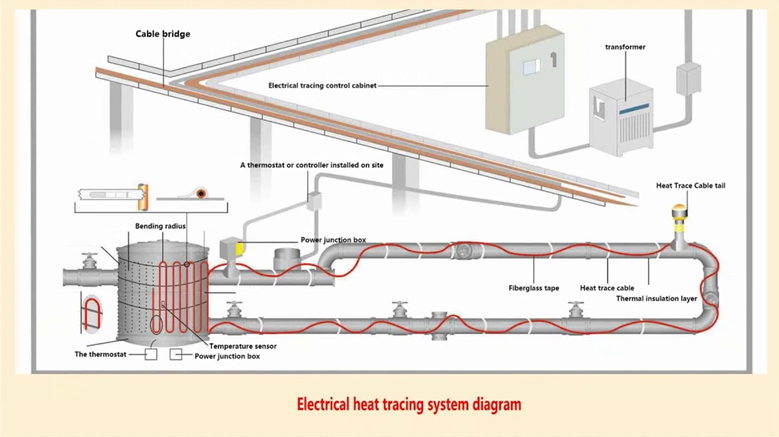

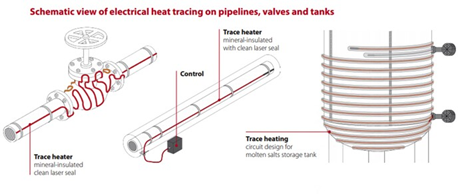

Electricians use constant wattage heat tracing cables to deliver the same heat along every meter. The cable has two parallel bus wires and a heating core. Each segment gives the same watts per meter. You buy pre-cut cables to match your pipe length. You clip the cable to the pipe, wrap insulation over it, and plug it in.

The heat stays even from start to end, so pumps and valves run at steady temperatures. Many UAE chemical plants pick these cables for process lines that need uniform warmth.

What Is a Series Resistance Cable?

Technicians pick series resistance heat tracing cables when they need a single-wire circuit. The cable uses one conductor whose resistance rises along its length. This design gives more heat near the power feed and less at the far end. You cut any cable length on site.

You seal the cut end with a termination kit and connect the other end to power. Roof gutter loops often use these cables to melt snow or ice. They also fit small process loops in food or HVAC systems.

Drawbacks of Constant Wattage vs Series Resistance Heat Tracing Cables

You can face issues if you choose the wrong cable for your task:

- Constant wattage cables require ordering exact lengths to avoid leftovers.

- Series resistance cables may overheat near the feed if you cut too long.

- Constant wattage systems cost more in materials up front.

- Series resistance runs can leave end segments too cool on long pipes.

- Mixing cable types ups your spare-parts inventory and training needs.

Feature Comparison Table

| Feature | Constant Wattage Cable | Series Resistance Cable |

|---|---|---|

| Heat Output | Fixed W/m | High near feed; low at end |

| Cut-to-Length Flexibility | No | Yes |

| Max Run Length | Unlimited with paralleled runs | 10–20 m |

| Temperature Control Uniformity | High | Medium |

| Installation Skill Level | Medium | Low |

| Common Use | Long pipelines | Short de-icing loops |

| Typical Warranty | 10 years | 5 years |

Top Approaches to Maintenance and Installation

Preserve the efficacy and safety of your heat tracing system by following these instructions:

- Mark the watt per meter heat loss for each pipe length.

- Use up to 50 °C daytime peaks UAE-rated insulation.

- Horizontal runs should have stainless-steel clips securing cables every 300 mm.

- Catch hot spots or cool regions by inserting a temperature sensor every 10 m.

- Before turning on electrical resistance, test for any damage.

Cost Analysis and ROI

Operators in the Jebel Ali Free Zone studied both cable types. They found:

- Constant wattage systems cost roughly 20 percent more on materials.

- These systems cut downtime by 15 percent through stable heat control.

- Series resistance setups save 10 percent on cable costs for short runs.

- Energy bills can rise if a long series resistance run stays too cool.

Here is a simple ROI table for a 100 m pipe section in Dubai:

| Cable Type | Material Cost (AED) | Annual Energy Savings (%) | Payback Period (years) |

|---|---|---|---|

| Constant Wattage Cable | 40,000 | 15 | 3 |

| Series Resistance Cable | 36,000 | 8 | 4.5 |

Choosing the Right Cable

Use this guide to pick between Constant Wattage vs Series Resistance Heat Tracing Cables for your site:

- Industrial pipe freeze protection solutions that span long distances need constant wattage cables.

- Roof and gutter de-icing loops often work best with series resistance cables.

- Self-regulating heat tracing cables can join a mix when ambient temps jump.

- Chemical plant temperature maintenance systems with critical setpoints favor constant wattage.

- Water treatment plant heat tracing design may split loads: long runs get constant wattage; short loops use series resistance.

Conclusion and Recommendations

Matching cable type to job cuts your energy bills and boosts uptime. Use constant wattage cables for long, critical process lines. Choose series resistance cables for short runs like gutter or small loop heating. Follow best practices on insulation, mounting, and testing to keep your system safe and trouble-free.

Need help with Constant Wattage vs Series Resistance Heat Tracing Cables? Reach out to our experts at Pak Link AE now to design a custom heat tracing solution for your UAE site.